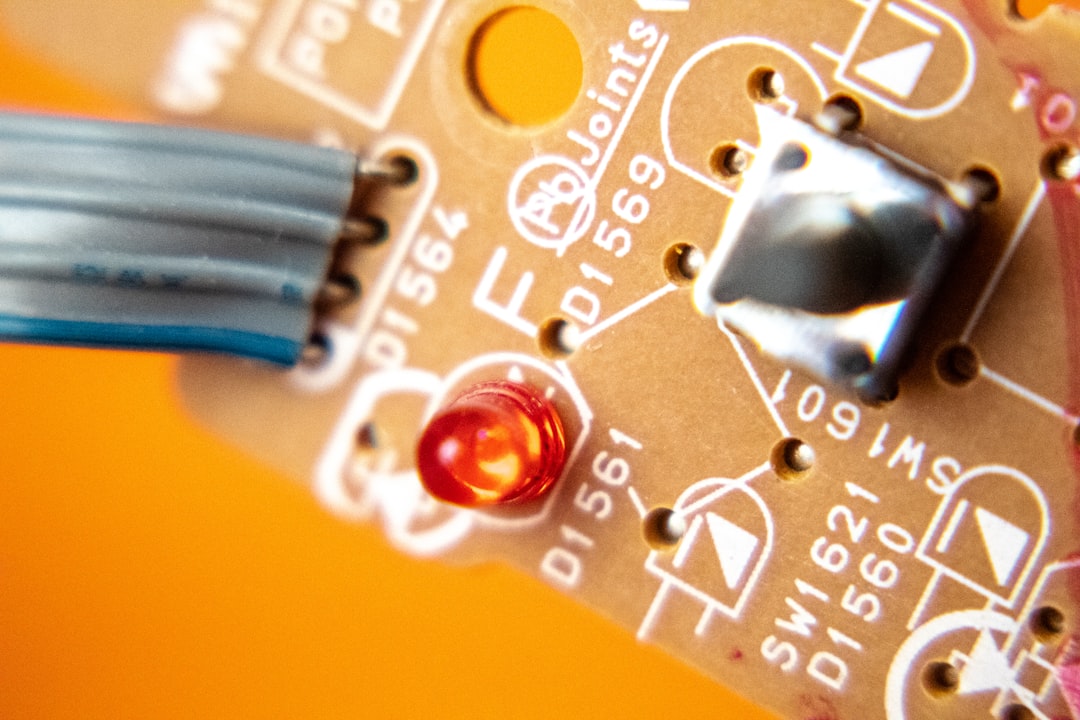

If you’ve ever tried soldering and ended up with a messy blob instead of a smooth, shiny connection, you’re not alone. The secret helper behind clean, strong solder joints is something called solder flux. It might sound like a spell from a science fiction movie, but it’s very real—and it’s super important.

What Is Solder Flux?

Solder flux is a chemical cleaning material. It prepares the metal surfaces that you want to solder. Think of it like soap for metal. It gets rid of oxides and grime so that the solder can stick better.

Before you solder, metals can be covered in a thin layer of oxidation. This gets in the way and makes it hard for solder to stick. Flux removes this oxidation and keeps it from coming back while the metal is still hot.

Why Do You Need It?

Great question! Here’s why:

- It cleans metal surfaces – Makes the joints nice and shiny so solder can stick.

- It prevents oxidation – Protects your solder area while you work.

- It improves flow – Helps solder spread smoothly over the connection.

- It makes stronger joints – Better flow means better electrical connections.

Without flux, your solder might just sit there like a grumpy blob. With flux, it flows like a champ.

Types of Flux

There are several types of flux, and each has its own strengths. Here’s a quick breakdown:

- Rosin Flux – Traditional and popular. It’s made from tree sap (yes, really!). It’s gentle and usually used in electronics.

- No-Clean Flux – Leaves little or no residue after soldering. Great when you can’t easily clean the board after soldering.

- Water-Soluble Flux – Strong stuff. It works great but needs to be washed off thoroughly after soldering. Perfect for critical electronics work.

- Paste Flux – Thick and goopy. Applied with a brush or syringe, it stays put even on vertical surfaces.

Choosing the right type of flux depends on what you’re soldering and how clean your workspace is.

Where Is Flux Used?

You’ll find flux used in:

- Electronics soldering

- Plumbing (though it’s a different kind of flux)

- Jewel making

- Automotive wiring

- Printed circuit board (PCB) repair

Basically, if you’re joining metal parts with solder, you probably need flux.

How to Use Flux Properly

Okay, so you’ve got your flux. Now what? Here’s a step-by-step:

- Clean the surfaces. Use a bit of isopropyl alcohol or a glass fiber pen. Get it nice and shiny.

- Apply the flux. Use a brush, syringe, or put it right on using a pre-fluxed solder wire.

- Heat the joint. Touch the soldering iron to the joint and let the flux do its job. You’ll see it start to bubble or sizzle when it activates.

- Add solder. Touch the solder wire to the joint (not the iron) and watch it flow smoothly over the metal.

- Clean up (if needed). Depending on which kind of flux you used, you might need to wash it off. Water-soluble flux definitely needs cleaning. No-clean flux usually doesn’t.

Tip: Do not leave active flux residue behind. It can corrode your connections over time!

Common Mistakes to Avoid

Even experienced makers make mistakes with flux. Here are some to watch out for:

- Using too much flux – More isn’t always better. A tiny bit usually does the trick.

- Not cleaning the board first – Flux can’t clean heavy grime—it’s not magic!

- Mixing flux types – Stick with one kind of flux per project, or you might get weird results.

- Overheating – If your solder turns dark or doesn’t flow, you might be burning the flux.

Flux is awesome, but it can’t fix every soldering problem. Practice makes perfect!

Fun Fact: Flux in Everyday Life

You might not realize it, but flux (or something like it) is everywhere. Ever baked cookies and sprayed your tray with non-stick spray? That’s your baking “flux.” It helps the cookies come off the tray easily. Same idea—but probably less tasty.

Safety First!

Flux is safe if you treat it with care. But here are some good habits:

- Ventilate your workspace – Flux fumes can get smoky. A small fan or fume extractor helps.

- Wash your hands afterward – Even “no-clean” can leave residue.

- Wear safety glasses – Splattering flux can be annoying or painful.

Some people also wear gloves, especially when using water-soluble flux. Safety never goes out of style!

Do You Always Need Extra Flux?

Nope! Some solder wire comes with flux built in. This is called flux-core solder. You can use it without adding extra flux in many cases.

But for extra tricky spots or old oxidized wires, using additional flux can make life a lot easier.

Cleaning Up After Using Flux

As we mentioned earlier, cleaning depends on your flux type:

- No-clean flux: Usually you can leave it. But if it looks messy, you can use a bit of isopropyl alcohol and a toothbrush.

- Rosin flux: Same cleaning method—alcohol scrub. Don’t skip it for circuits where looks and performance matter.

- Water-soluble: Definitely clean this off with water or a solvent. If left behind, it can lead to rust or corrosion.

Keeping your finished work clean not only looks better—it helps it last longer!

Final Thoughts

Solder flux might seem like an optional extra, but it’s actually a little miracle worker. It turns frustrating connections into smooth, sparkly, dependable ones. Whether you’re building your first robot or fixing a loose wire, flux is your friend.

So go forth, solder safely, and let your creations come to life—one shiny joint at a time!