In today’s technologically driven industries, the complexity of equipment and digital systems has reached unprecedented levels. As a result, the challenge of component and system obsolescence has grown into a pressing concern. Without a strategic approach to obsolescence management, industries face stalled production lines, unexpected maintenance costs, and increased risk across the supply chain. However, companies that proactively implement obsolescence management strategies see up to a 40% extension in equipment lifecycle and dramatically reduced supply chain disruptions.

What Is Obsolescence Management?

Obsolescence management is the process of identifying, assessing, and mitigating the impact of outdated components, software, and systems within a product or supply chain. Whether it’s due to supplier discontinuation, advances in technology, or regulatory changes, obsolescence can lead to significant disruptions. Effective obsolescence management ensures organizations can plan for, and adapt to, these changes before they become critical threats.

Why Obsolescence Matters in Supply Chains

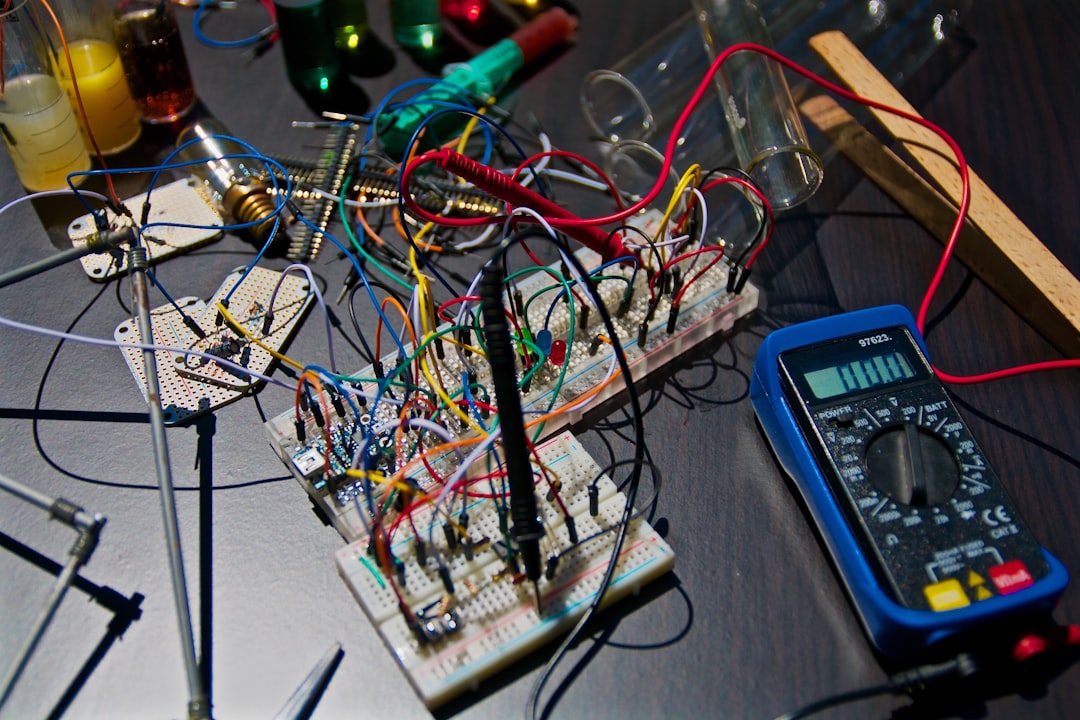

Modern supply chains are intricately tied to the availability of specific parts and software systems. A single obsolete microchip or outdated control system can cause delays in product manufacturing or even make entire pieces of equipment unusable.

Without preventative measures, businesses may face:

- Delivery Delays: When a component is no longer produced, sourcing replacements can take weeks or months.

- Increased Costs: Obsolete parts on the grey market come at a premium, often with questionable reliability.

- Regulatory Risks: Non-compliant systems may no longer meet safety or environmental standards.

- Downtime: Equipment depending on obsolete technology is prone to longer maintenance cycles or total operational failure.

How Obsolescence Management Works

Proactive obsolescence management helps mitigate these risks by creating scalable strategies that ensure components and systems are always supported or replaceable. The core steps of an obsolescence management program include:

- Inventory Assessment: Mapping current systems and components to identify at-risk or obsolete assets.

- Lifecycle Forecasting: Predicting when components or systems will reach end-of-life, allowing ample time for mitigation.

- Supplier Coordination: Working closely with vendors to plan last-time buys and identify newer alternatives.

- Data Tracking and Alerts: Leveraging digital tools to monitor component status and receive obsolescence alerts.

- Redesign and Retrofit Planning: Updating equipment and systems to accommodate alternative parts before obsolescence impacts operations.

Reducing Supply Chain Risk Through Strategic Planning

When obsolescence is managed strategically, a company turns a potential liability into a strength. One of the key ways it enhances the overall supply chain is by providing continuity of operations. By planning for legacy component replacement ahead of time, businesses avoid costly scrambles triggered by sudden discontinuations.

Moreover, organizations can establish long-term partnerships with suppliers and better negotiate service level agreements that include obsolescence clauses. These contracts often include access to alternate parts, dedicated product lifecycle support, and early end-of-life notifications. All of these tactics reduce uncertainty and support uninterrupted product delivery.

Extending Equipment Lifecycle by Up to 40%

Equipment replacement is a capital-intensive process, but through obsolescence management, the usable lifespan of machinery and systems can be significantly extended. Here’s how:

- Predictive Maintenance: Replacing critical electronic or mechanical components before failure helps maintain full functionality longer.

- Upgrade Pathways: Implementing modular systems where components can be swapped or upgraded delays the need for full equipment replacement.

- Retrofitting: Introducing compatible modern technologies into legacy systems keeps them operational and standards-compliant.

Organizations that embrace these techniques often see a 30-40% increase in serviceable equipment life, which translates to significant long-term cost savings, reduced capital expenditure, and better ROI from initial investments.

Industry Examples of Success

Numerous sectors, especially in aerospace, defense, manufacturing, and transportation, have embraced obsolescence management with remarkable results. For instance:

- Aviation: Airlines use obsolescence software tools to manage avionics part lifecycles. This cuts unscheduled maintenance and avoids emergency last-time buys.

- Defense: Military equipment with decades-long operational windows relies on long-term technology planning and retrofit strategies to stay mission-ready.

- Manufacturing: Leading factories use obsolescence tracking software integrated with ERP systems to ensure that their machines remain upgradeable and compliant with emerging regulations.

The Future of Obsolescence Management

With rapid technological evolution, obsolescence isn’t going away—it’s accelerating. That’s why digital transformation in obsolescence management is becoming vital. AI-powered predictive analytics, blockchain-based part traceability, and digital twins are all emerging tools to proactively manage risk and extend asset life.

Ultimately, organizations that adopt obsolescence management as a core part of their asset and supply chain strategy stand to gain not only reduced operational risk but also a significant boost in return on investment for their technology and infrastructure.

FAQs

-

What is the main goal of obsolescence management?

The primary goal is to reduce operational and supply chain risks by planning for the eventual discontinuation or unavailability of components or systems, thereby maintaining equipment operability and compliance. -

How does obsolescence management improve supply chain resilience?

It enables companies to anticipate disruptions, secure alternate suppliers, and reduce dependency on single-source or legacy components. -

Can small businesses benefit from obsolescence management?

Absolutely. Even small manufacturers or equipment operators can save significant costs and avoid downtime by implementing lightweight obsolescence tracking and risk mitigation strategies. -

Is software included in obsolescence planning?

Yes, enterprise software and control systems are often included, as end-of-support for software can affect compatibility, security, and regulatory compliance. -

How often should an obsolescence review be conducted?

It depends on the industry, but generally, a semi-annual or annual review is recommended to stay ahead of upcoming risks.